Highlights from the video

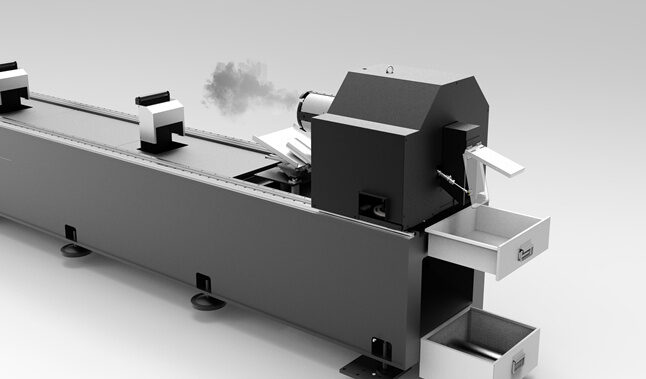

3D Laser Tube Cutting vs. 2D Laser Tube Cutting

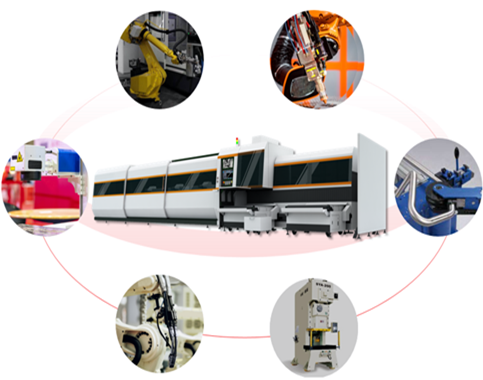

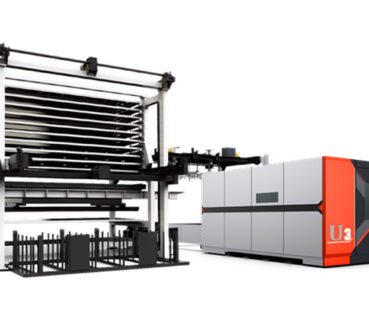

Need to Customize Your Automation Laser Solution?

GoldenLaser CNC system supports docking with unmanned material warehouse, robot automation, laser welding, laser marking, CNC bending, CNC stamping and other related processing technologies. It also supports embedding information production management mode to establish a complete advanced and intelligent vertical production and manufacturing system for pipe processing.

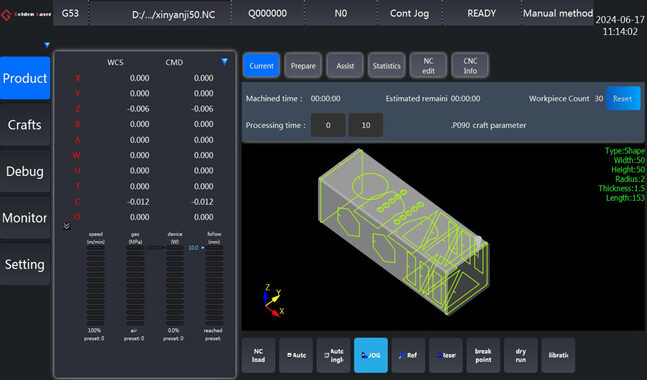

Models | i25-3D / i25A-3D | i35-3D / i35A-3D |

|---|---|---|

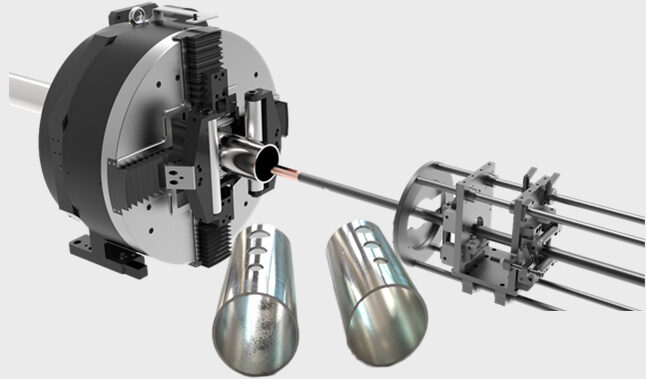

Processing pipe size range | round tube φ20- φ220 square tube 20*20-140*140mm | round tube φ20- φ350mm square tube φ20- φ250 U profile 20# I profile 20# |

Laser power | 1500W- 6000W | 3000W-12000W |

Max acceleration | 1.2g | 0.6g |

Positioning accuracy | 0.02mm | 0.05mm |

XY Axis positioning speed | 120m/min | 72m/min |

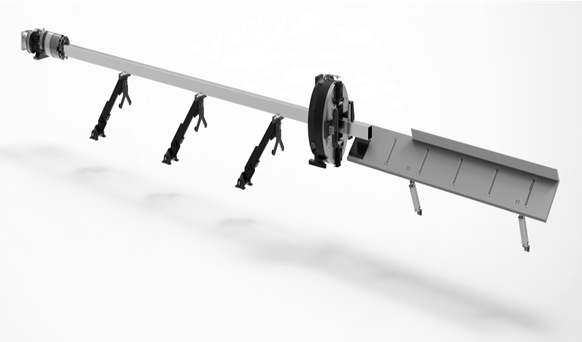

Bundle size | 800mm*800mm*6200mm | 800mm*800mm*8000mm |

Max weight for single tube | 150KG | 1200KG |

Waste length | ① When the front and rear chucks clamp the pipe at the same time, the tailing material is 180mm; ② When the front chuck is opened and only the rear chuck is used, the tailings are 80mm. | ① When the front chuck claw are opened, the shortest tail is 160mm, ② when the front chuck claw are not opened, the shortest tail is 220mm; |

Max load for loader | 2.5t | 2.5t |

Industries & Applications

We have you covered whether for structure material, auto parts, medical equipment, hardware, outdoor appliances, stainless steel tubes, carbon tubes, or aluminum tubes.